The operation of a clean room is essentially based on the principle of

forced recirculation of super-filtered air in a sealed room, ensuring

a completely clean environment by eliminating impurities that can

damage production.

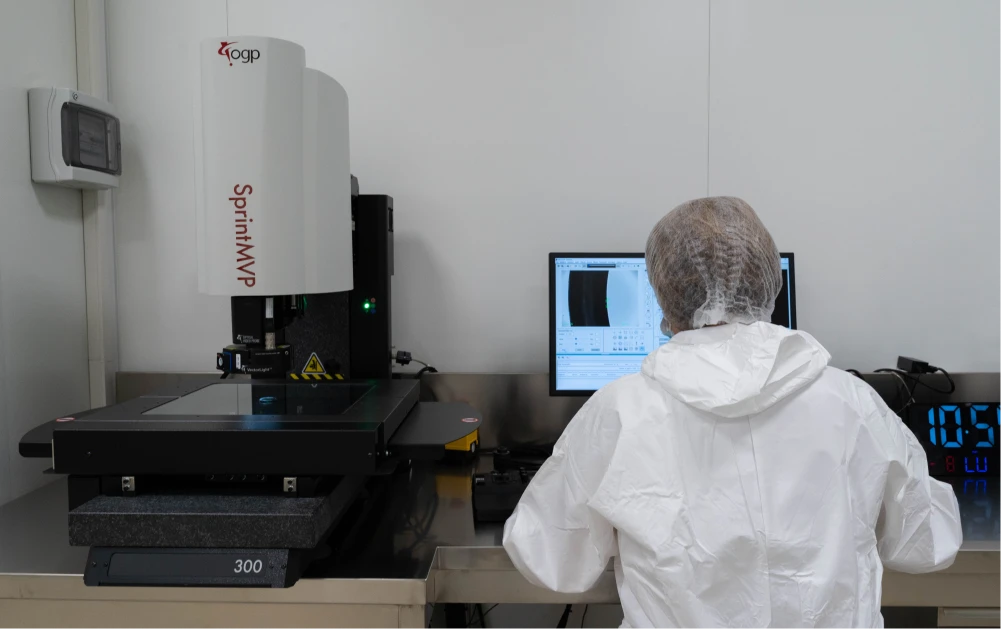

The clean room can be considered a small company within the company

where we find the entire production process from extrusion to

packaging. In our clean room we have both compression and injection

machines, a washing and post-curing system with a strict quality

control system.